I’m sure anyone who has anything to do with the operation of a hydraulic system, realizes and understands it needs to be an effective and smooth running operation. After all, if the system is not operating due to downtime caused by especially poor servicing, it is not being productive and money is just being thrown away. The most important component in any hydraulic system is the pump. If the pump breaks down, the system breaks down. It is like the human heart. If the human heart goes down, life ends. That’s it! Therefore, the wise decision would be to protect the pump. Possibly the two most effective components in the hydraulic system are the pump and the strainer that protects it. As the pump performs its job, the strainer is in place to capture the debris to ensure the pump can continue to function as it is designed to.

I’m sure anyone who has anything to do with the operation of a hydraulic system, realizes and understands it needs to be an effective and smooth running operation. After all, if the system is not operating due to downtime caused by especially poor servicing, it is not being productive and money is just being thrown away. The most important component in any hydraulic system is the pump. If the pump breaks down, the system breaks down. It is like the human heart. If the human heart goes down, life ends. That’s it! Therefore, the wise decision would be to protect the pump. Possibly the two most effective components in the hydraulic system are the pump and the strainer that protects it. As the pump performs its job, the strainer is in place to capture the debris to ensure the pump can continue to function as it is designed to.

Pumps are built to take a beating, but none the less, some prudent protection is in order to keep problems from occurring and to maintain an operation running at peak performance. The best cure for any possible problem is prevention, and the low cost of suction strainers is extremely beneficial. It is not uncommon to find items that have inadvertently fallen, been knocked or kicked, or somehow accidentally gone into the reservoir during servicing at some point. If a nut, bolt, or screw, or any object that isn’t supposed to be there, for instance, got into the suction line, it could be the end of the life of the pump.

Please install some sort of pressure drop indicator on the suction side so the delta P can be monitored. This will indicate if the strainer is reaching the end of its service life. If a strainer becomes indexed and flow is restricted, the strainer would collapse which will have disastrous results. The suction line does not require a fine filtering but a simple straining, merely to protect the pump. Too fine of filtering could very possibly cause cavitation to occur and this would cause additional problems. Also ensure the correct sized strainer, one that meets the system’s flow requirements is installed. If the strainer fails to meet certain requirements, it could also potentially cause irreversible damage to the system.

Both suction strainers and tank mounted strainers can be furnished for applications requiring anywhere up to 100 gpm, sometimes higher for special applications. Most are available for petroleum based fluid applications. That means the support tube or the core, and end caps would be made of plated steel. The wire mesh is pleated stainless steel and normally used in a suction strainer anywhere between 30 mesh (595 microns) and 100 mesh (149 microns).

Cross Reference Guide

Cross Reference Guide

Cross Reference Guide

Cross Reference Guide I’m sure anyone who has anything to do with the operation of a hydraulic system, realizes and understands it needs to be an effective and smooth running operation. After all, if the system is not operating due to downtime caused by especially poor servicing, it is not being productive and money is just being thrown away. The most important component in any hydraulic system is the pump. If the pump breaks down, the system breaks down. It is like the human heart. If the human heart goes down, life ends. That’s it! Therefore, the wise decision would be to protect the pump. Possibly the two most effective components in the hydraulic system are the pump and the strainer that protects it. As the pump performs its job, the strainer is in place to capture the debris to ensure the pump can continue to function as it is designed to.

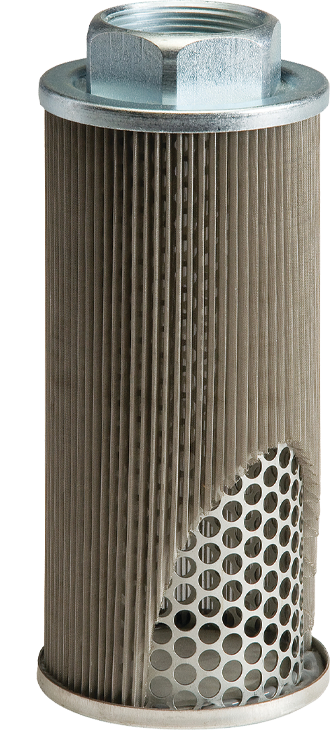

I’m sure anyone who has anything to do with the operation of a hydraulic system, realizes and understands it needs to be an effective and smooth running operation. After all, if the system is not operating due to downtime caused by especially poor servicing, it is not being productive and money is just being thrown away. The most important component in any hydraulic system is the pump. If the pump breaks down, the system breaks down. It is like the human heart. If the human heart goes down, life ends. That’s it! Therefore, the wise decision would be to protect the pump. Possibly the two most effective components in the hydraulic system are the pump and the strainer that protects it. As the pump performs its job, the strainer is in place to capture the debris to ensure the pump can continue to function as it is designed to. Suction Strainer

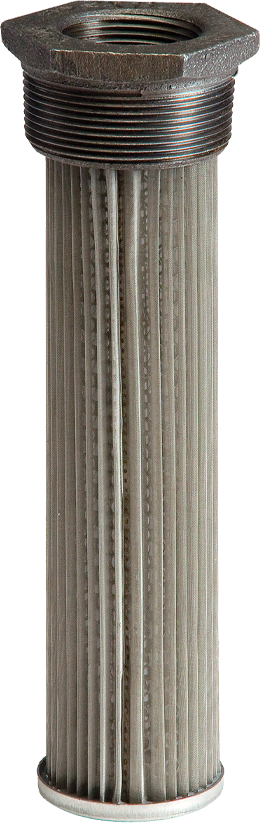

Suction Strainer Tank Mounted Suction Strainer

Tank Mounted Suction Strainer the relief valve is open, allowing full, unfiltered flow to pass through it. This would be an indication to service the strainer.

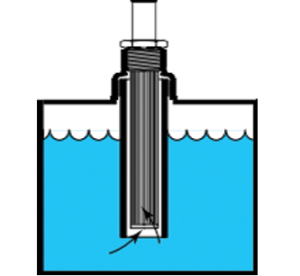

the relief valve is open, allowing full, unfiltered flow to pass through it. This would be an indication to service the strainer. Tank mounted strainers can also be used a couple of other ways. They can be installed through a tank top by welding a standard bell reducer (coupler) over a hole cut in the top of the reservoir. Please note the image. A standpipe threaded into the coupling, needs to be only long enough to stay below the lowest fluid level the reservoir will have. The strainer can be removed for servicing without draining the reservoir. There is no need to access the interior of the reservoir to service the tank mounted strainer.

Tank mounted strainers can also be used a couple of other ways. They can be installed through a tank top by welding a standard bell reducer (coupler) over a hole cut in the top of the reservoir. Please note the image. A standpipe threaded into the coupling, needs to be only long enough to stay below the lowest fluid level the reservoir will have. The strainer can be removed for servicing without draining the reservoir. There is no need to access the interior of the reservoir to service the tank mounted strainer. The tank mounted strainer can also be used as an “in-line” strainer with a simple modification. Using standard pipe fittings a “housing” for a strainer can quickly be made and threaded in-line between the inlet line leaving the reservoir, and the pump.

The tank mounted strainer can also be used as an “in-line” strainer with a simple modification. Using standard pipe fittings a “housing” for a strainer can quickly be made and threaded in-line between the inlet line leaving the reservoir, and the pump.