888-354-0291

740-622-3307

111 North 14th St • PO Box 218 • Coshocton, OH 43812

- Capabilities

- Standard Products

Cross Reference Guide

Cross Reference Guide- H7 Series Female Suction Strainers

- H7 Series Male Suction Strainers

- Filler Breather – Threaded Style

- Filler Breather – Bayonet Style

- SAE Tank Mount Suction Strainers

- NPT Tank Mount Suction Strainers

- NPT Weld Flanges for Hydraulic Tanks and Reservoirs

- P7 Series Female Nylon Suction Strainers

- P7 Series Male Nylon Suction Strainers

- Flow Diffusers

- SP Series Spin-On Hydraulic Filters

- Tank Accessories

- Male to Male NPT Tank Mount Suction Strainers

- Tank Mount Diffusers

- Model “OS” 5.9″ Suction Strainers

- Model “OS” 8.1″ Suction Strainers

- Return Strainers

- Hose Barb Tank Mount Suction Strainers

- Pipe Mounted Suction Screens

- “PS” Suction Strainers for Water and Petroleum-Based Fluids

- All-Nylon Suction Strainers

- Custom Products

- About

- Learning Center

- Contact

Cross Reference Guide

Cross Reference Guide

When was the last time you couldn’t find a source for the filter you need? Or when could you find a source but lead time was months out? Or the price was in orbit? From concept, to design, to order, to manufacturing, to delivery, OFCO should be your next contact. OFCO specializes in custom made filters along with our standard quick-ship products. You will find our lead times very desirable and working with us is extremely easy. There isn’t much we can’t make, and if we can’t we’ll tell you. If we can, we’ll tell you that, too. We will always be honest and “up front” with you. You will like our pricing as well, and all our products are made in the USA at our plant in Coshocton, Ohio. All it takes is one phone call, fax, or e-mail, to bring you on board. We make solutions for your problems.

When was the last time you couldn’t find a source for the filter you need? Or when could you find a source but lead time was months out? Or the price was in orbit? From concept, to design, to order, to manufacturing, to delivery, OFCO should be your next contact. OFCO specializes in custom made filters along with our standard quick-ship products. You will find our lead times very desirable and working with us is extremely easy. There isn’t much we can’t make, and if we can’t we’ll tell you. If we can, we’ll tell you that, too. We will always be honest and “up front” with you. You will like our pricing as well, and all our products are made in the USA at our plant in Coshocton, Ohio. All it takes is one phone call, fax, or e-mail, to bring you on board. We make solutions for your problems.

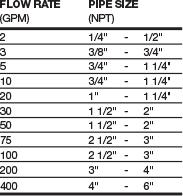

Last time we mentioned flow rate to be considered when selecting filters. Well, with flow rate, pipe size goes hand in hand. The filter must be properly sized to keep the pressure drop compatible with the fluid passing through it. A pump putting out 50 gpm, for example, will create less pressure drop when flowing through a 3″ npt pipe than through a 1″ npt pipe. The pipe size will help focus filter selection. This general reference chart relates pipe size to flow rate.

Last time we mentioned flow rate to be considered when selecting filters. Well, with flow rate, pipe size goes hand in hand. The filter must be properly sized to keep the pressure drop compatible with the fluid passing through it. A pump putting out 50 gpm, for example, will create less pressure drop when flowing through a 3″ npt pipe than through a 1″ npt pipe. The pipe size will help focus filter selection. This general reference chart relates pipe size to flow rate.