888-354-0291

740-622-3307

111 North 14th St • PO Box 218 • Coshocton, OH 43812

- Capabilities

- Standard Products

Cross Reference Guide

Cross Reference Guide- All-Nylon Suction Strainers

- Filler Breather – Bayonet Style

- Filler Breather – Threaded Style

- Flow Diffusers

- H7 Series Male Suction Strainers

- H7 Series Female Suction Strainers

- Hose Barb Tank Mount Suction Strainers

- Model “OS” 8.1″ Suction Strainers

- Model “OS” 5.9″ Suction Strainers

- Suction Strainers: NPT Tank Mount

- P7 Series Male Nylon Suction Strainers

- P7 Series Female Nylon Suction Strainers

- Pipe Mounted Suction Screens

- “PS” Suction Strainers for Water and Petroleum-Based Fluids

- SP Series Spin-On Hydraulic Filters

- Return Strainers

- SAE Tank Mount Suction Strainers

- Tank Accessories

- Tank Mount Diffusers

- Custom Products

- About

- Learning Center

- Contact

Cross Reference Guide

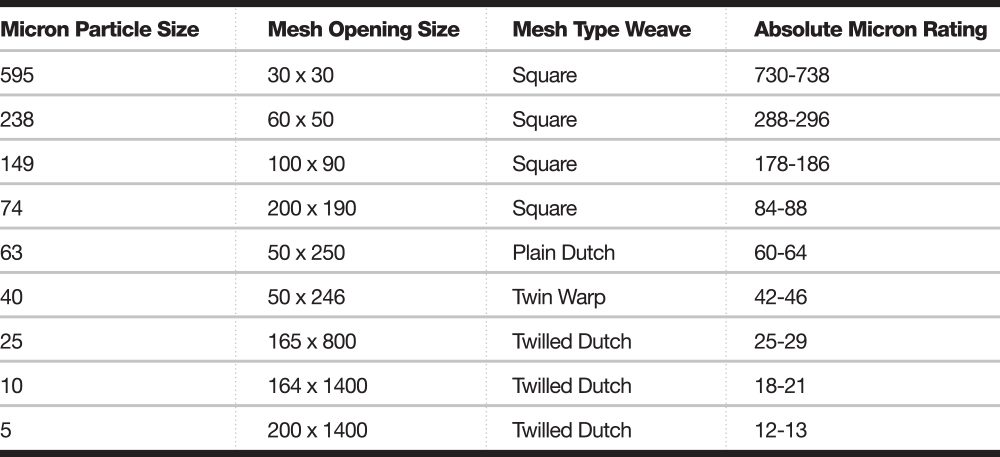

Cross Reference Guide Wire cloth has rarely been associated with an absolute rating. Information is available in some of the more standard sizes, however. Remember, wire cloth people talk in terms of mesh while filter people mostly talk in terms of micron. You can use the chart below as a “general” reference to wire cloth and its specifications.

Wire cloth has rarely been associated with an absolute rating. Information is available in some of the more standard sizes, however. Remember, wire cloth people talk in terms of mesh while filter people mostly talk in terms of micron. You can use the chart below as a “general” reference to wire cloth and its specifications.