888-354-0291

740-622-3307

111 North 14th St • PO Box 218 • Coshocton, OH 43812

- Capabilities

- Standard Products

Cross Reference Guide

Cross Reference Guide- H7 Series Female Suction Strainers

- H7 Series Male Suction Strainers

- Filler Breather – Threaded Style

- Filler Breather – Bayonet Style

- SAE Tank Mount Suction Strainers

- NPT Tank Mount Suction Strainers

- NPT Weld Flanges for Hydraulic Tanks and Reservoirs

- P7 Series Female Nylon Suction Strainers

- P7 Series Male Nylon Suction Strainers

- Flow Diffusers

- SP Series Spin-On Hydraulic Filters

- Tank Accessories

- Male to Male NPT Tank Mount Suction Strainers

- Tank Mount Diffusers

- Model “OS” 5.9″ Suction Strainers

- Model “OS” 8.1″ Suction Strainers

- Return Strainers

- Hose Barb Tank Mount Suction Strainers

- Pipe Mounted Suction Screens

- “PS” Suction Strainers for Water and Petroleum-Based Fluids

- All-Nylon Suction Strainers

- Custom Products

- About

- Learning Center

- Contact

Cross Reference Guide

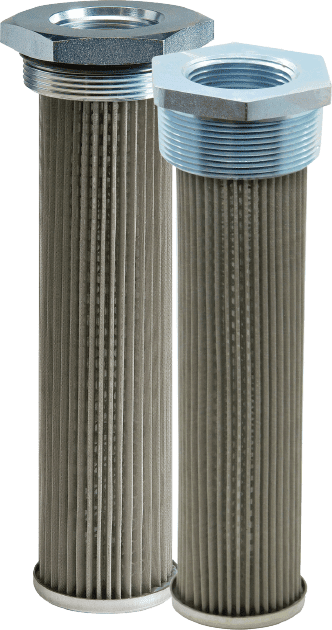

Cross Reference Guide Hydraulic suction lines are a MUST when it comes to filtering process fluid. You have heard us promote suction straining since we began operation in 1945. The pump is the most critical component in the system. If the pump goes down, the system goes down. Period. There are multiple ways to prevent this. At Ohio Fabricators we have answered your questions and solved your problems since day one. We want to now highlight tank mounted strainers.

Hydraulic suction lines are a MUST when it comes to filtering process fluid. You have heard us promote suction straining since we began operation in 1945. The pump is the most critical component in the system. If the pump goes down, the system goes down. Period. There are multiple ways to prevent this. At Ohio Fabricators we have answered your questions and solved your problems since day one. We want to now highlight tank mounted strainers.

In Newsletter #25, we touched on causes that affect system performance. If we continue to review what happens when these conditions are not properly controlled, the presence of dirt can initiate one or more of the following undesirable conditions.

In Newsletter #25, we touched on causes that affect system performance. If we continue to review what happens when these conditions are not properly controlled, the presence of dirt can initiate one or more of the following undesirable conditions. Hydraulics Symbol Quiz

Hydraulics Symbol Quiz