888-354-0291

740-622-3307

111 North 14th St • PO Box 218 • Coshocton, OH 43812

- Capabilities

- Standard Products

Cross Reference Guide

Cross Reference Guide- H7 Series Female Suction Strainers

- H7 Series Male Suction Strainers

- Filler Breather – Threaded Style

- Filler Breather – Bayonet Style

- SAE Tank Mount Suction Strainers

- NPT Tank Mount Suction Strainers

- NPT Weld Flanges for Hydraulic Tanks and Reservoirs

- P7 Series Female Nylon Suction Strainers

- P7 Series Male Nylon Suction Strainers

- Flow Diffusers

- SP Series Spin-On Hydraulic Filters

- Tank Accessories

- Male to Male NPT Tank Mount Suction Strainers

- Tank Mount Diffusers

- Model “OS” 5.9″ Suction Strainers

- Model “OS” 8.1″ Suction Strainers

- Return Strainers

- Hose Barb Tank Mount Suction Strainers

- Pipe Mounted Suction Screens

- “PS” Suction Strainers for Water and Petroleum-Based Fluids

- All-Nylon Suction Strainers

- Custom Products

- About

- Learning Center

- Contact

Cross Reference Guide

Cross Reference Guide What is the working pressure of the system? The answer to this question will let designers choose a filter that will withstand that anticipated pressure. If the filter in place cannot withstand the pressure, it will collapse, lose its integrity, and break down, not to mention it could cause possible breakdown of the entire system. To make matters worse, when a filter collapses, fragments of the epoxy and media can travel downstream and cause other equipment damage. The size of the filter, too, should be able to handle the flow and pressure without adding additional restriction on the media (see Part 2). Next time we will cover different types of fuel. Stay tuned.

What is the working pressure of the system? The answer to this question will let designers choose a filter that will withstand that anticipated pressure. If the filter in place cannot withstand the pressure, it will collapse, lose its integrity, and break down, not to mention it could cause possible breakdown of the entire system. To make matters worse, when a filter collapses, fragments of the epoxy and media can travel downstream and cause other equipment damage. The size of the filter, too, should be able to handle the flow and pressure without adding additional restriction on the media (see Part 2). Next time we will cover different types of fuel. Stay tuned. Ohio Fabricators is striving to be your supplier for all your hydraulic components. Please take a look at our two newest items. They are great complements to your hydraulic system.

Ohio Fabricators is striving to be your supplier for all your hydraulic components. Please take a look at our two newest items. They are great complements to your hydraulic system.

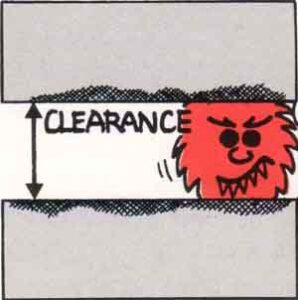

Did you know that by controlling the level of contamination (dirt) to accept-able levels you can eliminate as much as 80 percent of the potential causes of system failure? That is extremely important when you consider high equipment costs and our dependence on today’s sophisticated and complex hydraulic fluid power systems.

Did you know that by controlling the level of contamination (dirt) to accept-able levels you can eliminate as much as 80 percent of the potential causes of system failure? That is extremely important when you consider high equipment costs and our dependence on today’s sophisticated and complex hydraulic fluid power systems.